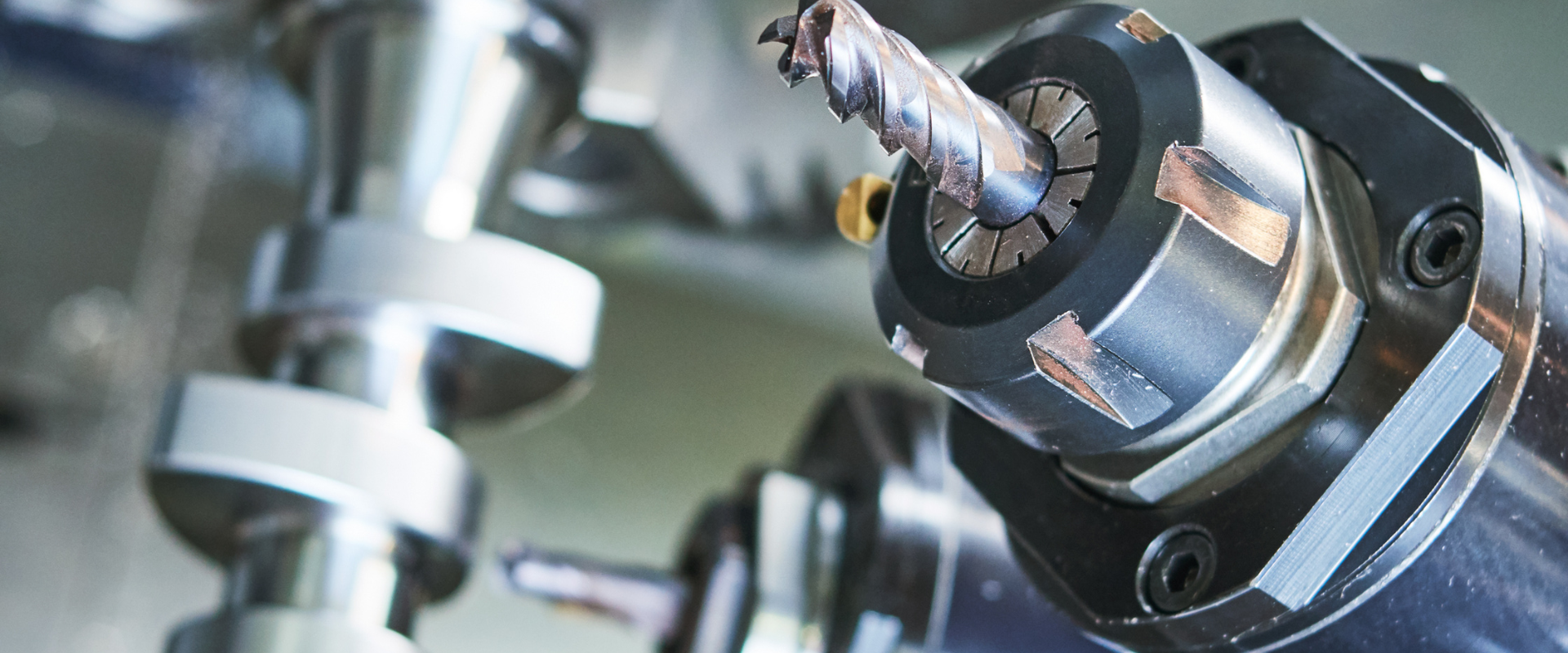

The convergence of cyber-physical systems in Industry 4.0 isn’t just automating factories—it’s transforming precision manufacturing into a hyper-connected, data-driven ecosystem. For sectors like aerospace, medical devices, and automotive, where micron-level accuracy is non-negotiable, this revolution unlocks unprecedented quality, agility, and cost efficiency.

Key Innovations Driving Change

- IoT-Enabled Machining:

- Real-time monitoring of CNC machines via embedded sensors tracks tool wear, thermal drift, and vibration.

- Impact: 30–50% reduction in scrap rates through predictive adjustments (McKinsey data).

- AI-Driven Process Optimization:

- Machine learning algorithms analyze historical data to optimize cutting parameters (speed, feed, depth) for specific materials.

- Example: Adaptive machining compensates for material inconsistencies mid-process.

- Closed-Loop Quality Control:

- In-line metrology (e.g., laser scanners) feeds data back to machines for automatic recalibration, achieving CpK >2.0.

- Digital Thread Integration:

- End-to-end data flow from CAD/CAM to production and QA ensures traceability and rapid design iterations.

- ROI & Operational Benefits

- 50% Faster Time-to-Market: Rapid prototyping via additive manufacturing + digital twins.

- 20–35% Lower Operational Costs: Energy optimization, reduced downtime, and minimal rework.

- Zero-Defect Manufacturing: Statistical process control (SPC) powered by real-time analytics.

- Implementation Roadmap

- Start with IIoT Sensors: Retrofit legacy equipment with low-cost vibration/temperature sensors.

- Deploy Edge Computing: Process data locally to avoid latency in critical operations.

- Upskill Workforce: Transition machinists into "data orchestrators" via AR-assisted troubleshooting.

Industry 4.0 isn't just about automation—it's about creating an intelligent ecosystem where every component, machine, and process is optimized for maximum efficiency and quality.

Impact on Different Sectors

Aerospace

Reduced production time by 40% while maintaining strict quality standards.

Medical Devices

Achieved 99.99% accuracy in critical component manufacturing.

Automotive

Streamlined supply chain with real-time inventory management.

Conclusion

Industry 4.0 shifts precision manufacturing from skill-dependent craftsmanship to data-empowered science. Companies investing in IIoT, AI, and closed-loop systems today will dominate tomorrow’s high-tolerance component markets.